Our services

Quality “Made in Rhineland-Palatinate

More than 55 years Ecotex GmbH & Co. KG

For more than 55 years we have been supplying laundries all over the world with our used machines. We stand for quality “Made in Germany”. Here we feel at home! In Plaidt in the Eifel region – in the heart of Rhineland-Palatinate – we produce for the European market in our in-house workshop.

Machine modernization is a matter of trust. We are aware of this responsibility. Because we care about quality, we work with the machines of leading and well-known manufacturers. With our offer we cover the complete range of industrial laundries: From used washing lines, dewatering presses, centrifuges, dryers, infeed machines, ironers, folding machines and tunnel finisher systems to transport technology and belts.

Do you want to learn more about us and our work? Feel free to contact us.

Consulting & Planning

Everything from one source

A hygienically designed laundry starts with well-thought-out planning. Ecotex accompanies you from the individual consultation, considering all economic aspects, through the careful planning to the professional installation and training of your employees. All in all: We are there for you at every stage – see for yourself the benefits of our competent and professional advice!

Energetic design

At Ecotex, we place great emphasis on the efficient and sustainable use of energy in laundry technology. Our experts support you in the energy design of your plant to optimize energy consumption and reduce costs.

We take into account various factors such as electricity and water consumption as well as heat recovery. By using the latest technologies and integrating energy-efficient components, we can develop customized solutions for your laundry.

Our goal is to minimize the environmental footprint of your facility without compromising performance and efficiency. By designing for energy efficiency, you can not only save energy costs, but also contribute to environmental protection.

Our experienced engineers are available to perform a detailed analysis of your requirements and develop a customized solution. We also take into account the legal requirements and standards in the field of energy efficiency.

Economic efficiency analysis

Optimize the profitability of your laundry with our professional profitability analysis in three parts: Recording, calculation and allocation of your individual laundry items, preparation of an investment cost proposal as well as summary of your total laundry costs and calculation of the average laundry price per kilogram.

The economic analysis is carried out in three parts:

- Recording, calculation and allocation of your individual laundry items

- Elaboration of an investment cost proposal and

- Summary of your total laundry costs and calculation of the average laundry price per kilogram.

To give you a comprehensive overview of your laundry costs, we summarize all relevant factors. We take into account both the ongoing operating costs and the investment costs. Based on this data, we calculate the average price per kilogram for your laundry. This information is not only important for your own calculation, but also for pricing to your customers.

Our experts are available to perform a comprehensive profitability analysis of your laundry. Contact us to learn more about our profitability analysis services and optimize your laundry costs.

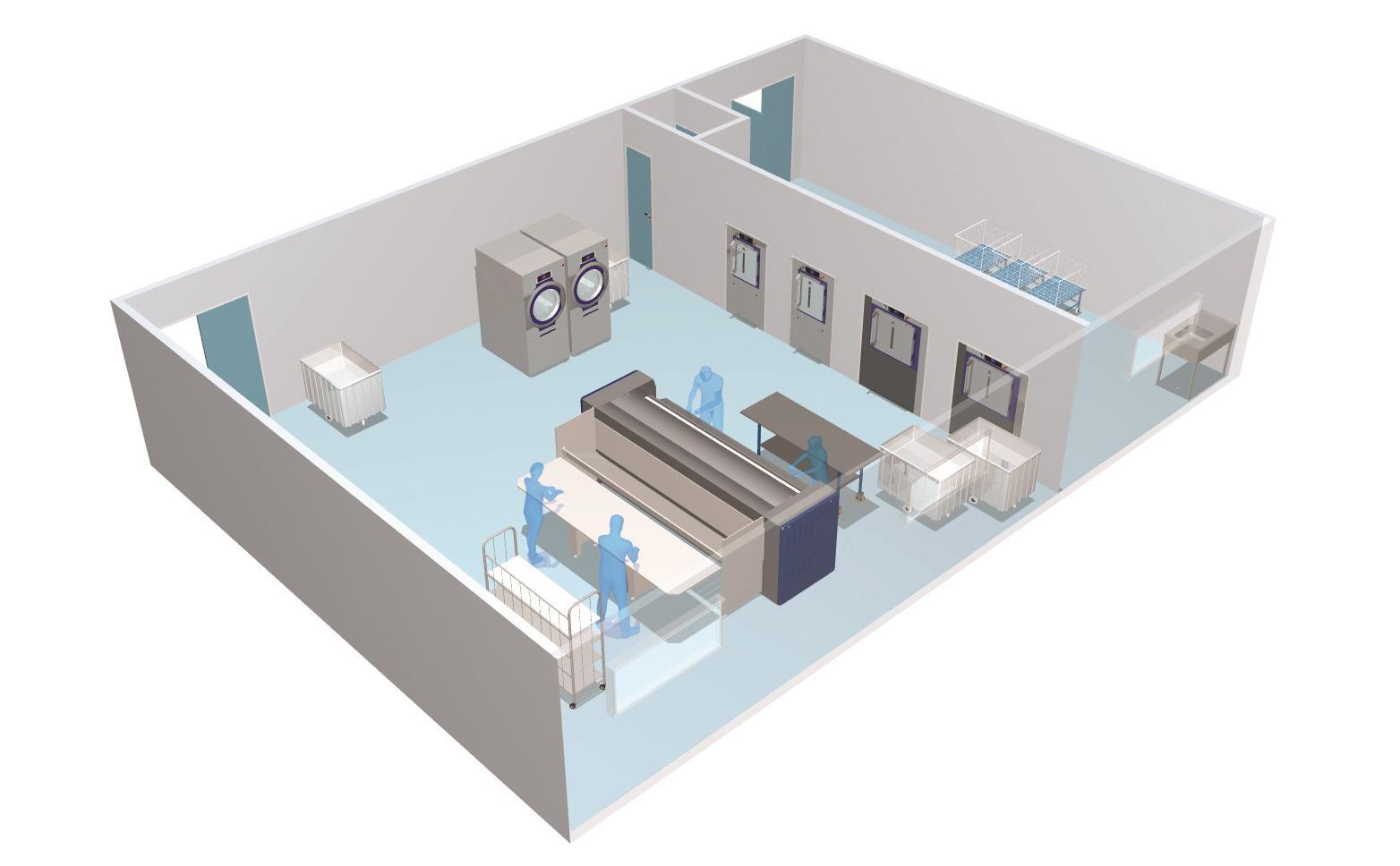

Creation of a setup proposal

At Ecotex, we offer comprehensive support for the optimal design of your laundry facilities. Our experts will create furnishing proposals for you in 2D and 3D, specifically tailored to your individual premises.

Using the latest CAD software, we develop detailed 2D plans that give you a precise idea of the layout of the machines and work areas in your plant. These plans take into account all relevant aspects such as space requirements, workflow and ergonomic considerations to ensure efficient and smooth operations.

In addition, we create impressive 3D visualizations for you, which offer a realistic representation of your future laundry equipment. You can virtually experience the spatial arrangement of the machines and the entire atmosphere of your operation even before the implementation takes place.

Modernization of customer-owned machines

It doesn’t always have to be new: Industrial laundry technology – “second-hand thinking

Ecotex is much more than second-hand technology. Because we ask the right questions right from the start: Which machines make sense for your needs? Do all the selected parts fit together optimally? Are the operating premises suitable for the selected plant? Upon request, we can create an AutoCAD planning drawing tailored to your needs.

From the center of Europe for Europe: At our corporate headquarters in Germany, we plan, renew and manufacture your plant. Whether individual machines or complete laundry equipment – we deliver and install your reconditioned equipment worldwide for you. We also take over your used machines. Feel free to contact us, we will make you an attractive offer.

As a machine modernizer of used, industrial laundry technology, our machines receive a new, updated nameplate after the general overhaul, including the necessary EU declaration of conformity and CE marking. This way you are always up to date with the latest technology.

We offer the right solution for every budget: from cost-effective basic solutions to business devices with warranty, used and refurbished or customized to your needs.

BASIC

ECONOMY

BUSINESS